Microwaves drill ceramicsSilent, dust-free drill melts

mini-holes in glass and concrete.

18 October 2002

PHILIP

BALL

|

|

The microwave drill in

action.

Š Science/E.

Jerby |

| movie | |

A microwave drill can bore through materials such as

concrete and glass, silently and without creating dust.

By heating a target to nearly 2,000 ēC, the microwaves

soften it up enough for a small rod to be pushed

through.

"It should provide a low-cost solution for a variety

of needs," say the drill's inventors Eli Jerby and his

colleagues at Tel Aviv University in Israel1.

It can make holes between a millimetre and a centimetre

wide, and could find use, for example, in the production

of ceramic components for cars and planes, in building

construction and in geological engineering.

Using heat to cut and drill materials is nothing new.

Lasers are already widely used to make incisions or

holes as narrow as a thousandth of a millimetre. But

laser drilling is too expensive for many routine

engineering jobs, whereas the microwave drill costs

little more than a mechanical one.

|

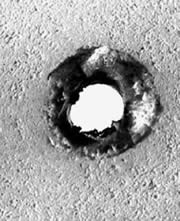

| A microwave-drilled hole

in alumina. |

| Š Science/E.

Jerby | | |

The drill bit is a needle-like antenna that emits

intense microwave radiation. The microwaves create a hot

spot around the bit, melting or softening the material

so that the bit can be pushed in.

But the drill can't bore through everything

effectively. Sapphire's melting point, for instance, is

too high. And steel conducts heat too well for a hot

spot to develop. But the device works fine on rocks and

concrete. In fact, the heat may even strengthen holes'

walls in ceramics by welding together the fine grains in

the material.

To use the drill, workers would have to be shielded

from the intense microwave radiation it produces. The

inventors claim that a simple shielding plate put in

front of the drill bit is enough to meet common safety

standards. |